$63.95 Ex Tax: $63.95

$52.28 Ex Tax: $52.28

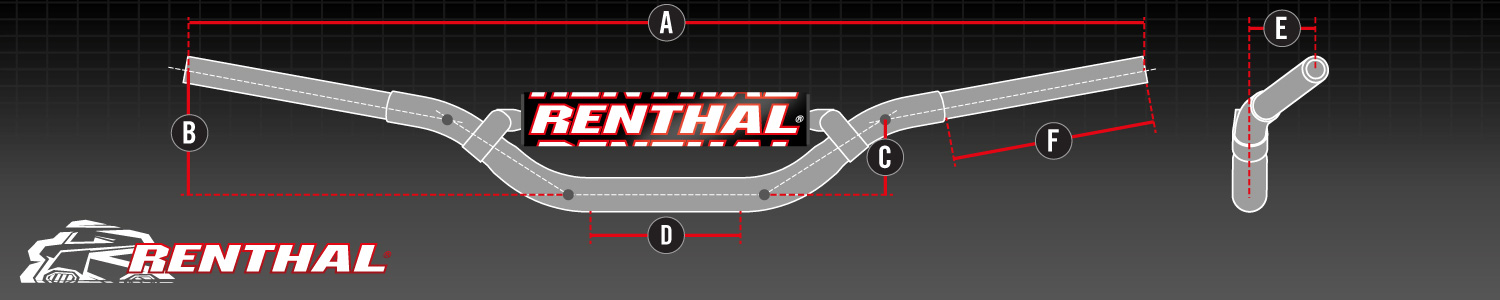

| Name | Part Number | A | B | C | D | E | F | Prices From: | Purchase | |

|---|---|---|---|---|---|---|---|---|---|---|

| 464U-530 ULTRALIGHT, 16T | 464U-530-16P | - | - | - | - | - | - | $63.95 Ex Tax: $63.95 | ||

| 309U-530 ULTRALIGHT, 16T - 28% Off | 309U-530-16P | - | - | - | - | - | - | $52.28 Ex Tax: $52.28 | ||

| Dimensions Explained | ||||||||||