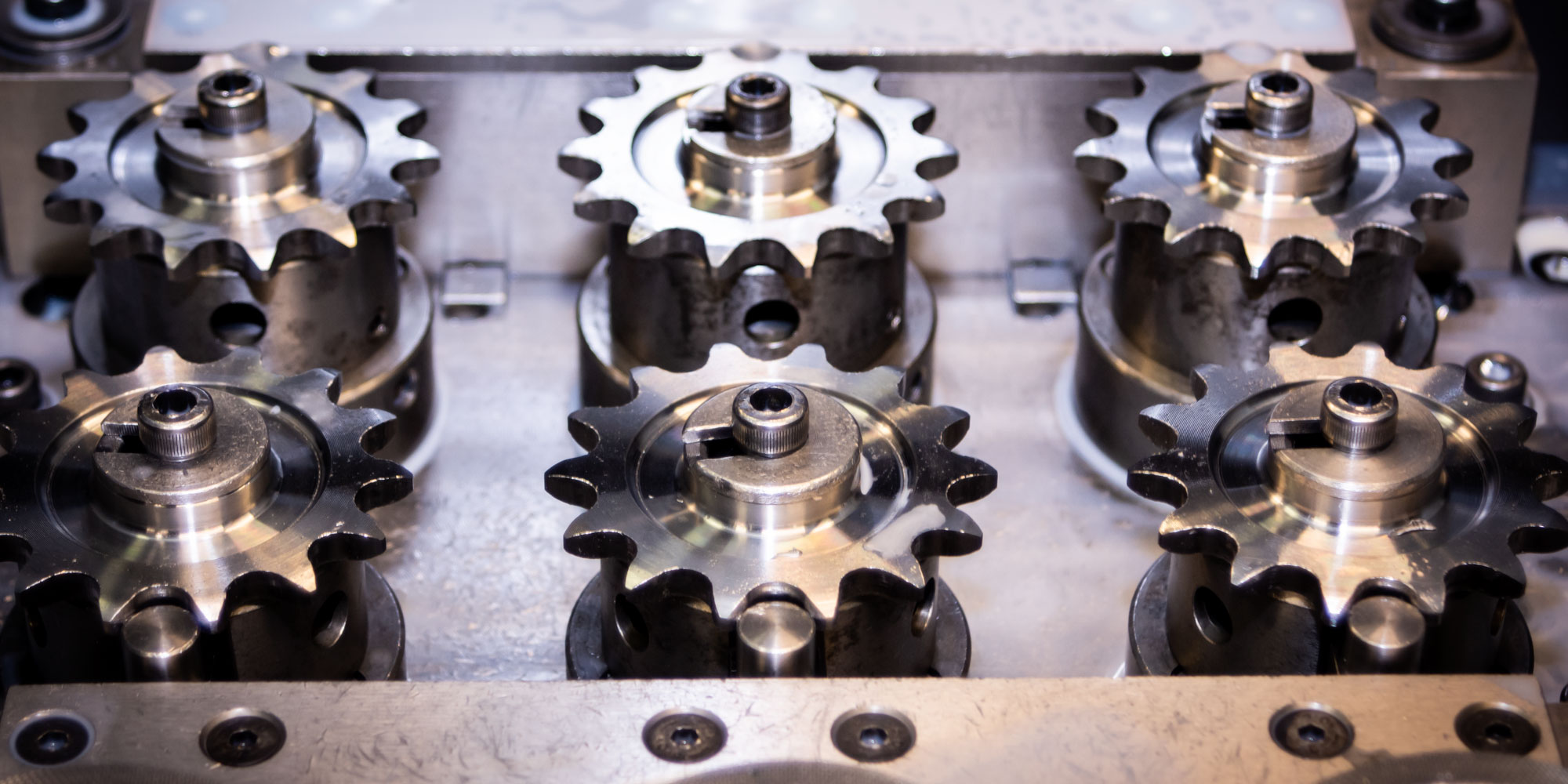

Renthal Front Chainwheels are carefully crafted in our state-of-the-art manufacturing facility in Manchester, UK using only the highest-grade raw materials available.

Using advanced computer engineering alongside CNC machining, Renthal consistently achieves perfect concentricity, fitment, load dispersion and uncompromising strength whilst ensuring maximum power delivery from each and every motocross front sprocket we produce.

As a safety critial external drive component, Renthal prides itself on creating the number one choice of motocross front sprockets as used by the world's premier athletes and race teams.

For the best way to find the correct chainwheel for your motorcycle, use our Fit My Bike Parts Finder.